Safety Integrity Level (SIL) in Oil and Gas Industry

Safety Integrity Level (SIL) is a critical safety performance metric used in the oil and gas industry to quantify the reliability and effectiveness of safety instrumented systems. SIL represents the relative level of risk reduction provided by a Safety Instrumented Function (SIF) and is expressed as the probability of failure on demand (PFD).

Definition and Purpose

SIL is defined as a discrete level (one out of four possible levels) that specifies the probability of a safety instrumented system failing to perform its intended safety function when required. In the oil and gas industry, SIL is vital due to the inherent risks associated with operations such as drilling, refining, and transporting hazardous materials.

The primary purpose of SIL is to:

-

Quantify safety system performance based on probability of failure on demand

-

Ensure adequate risk reduction for safety-critical processes

-

Provide a standardized framework for safety system design and assessment

-

Support regulatory compliance and industry best practices

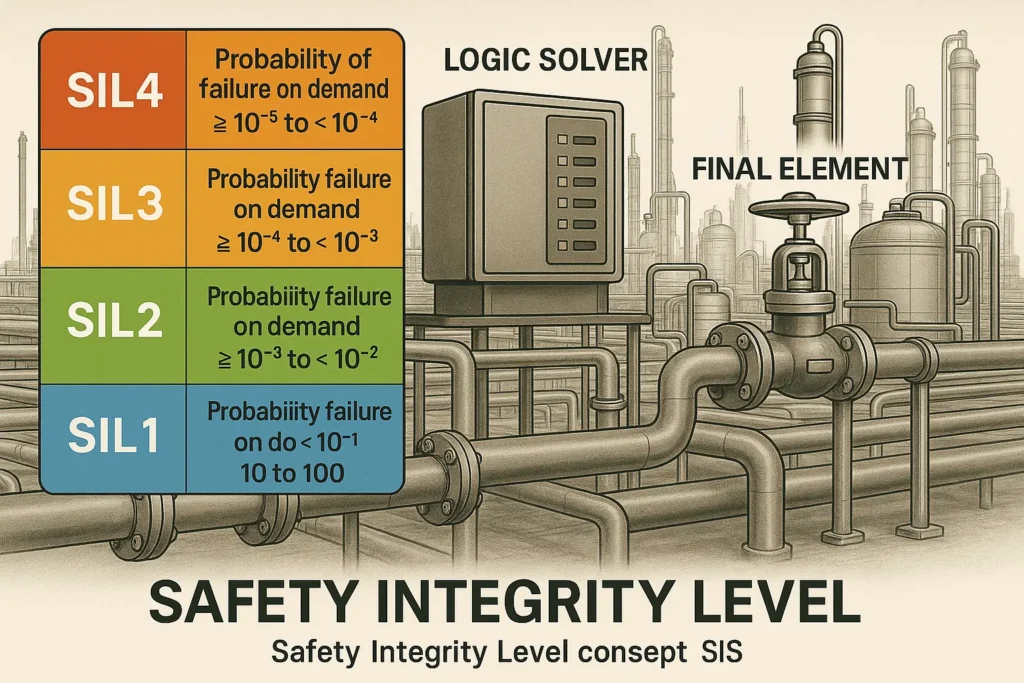

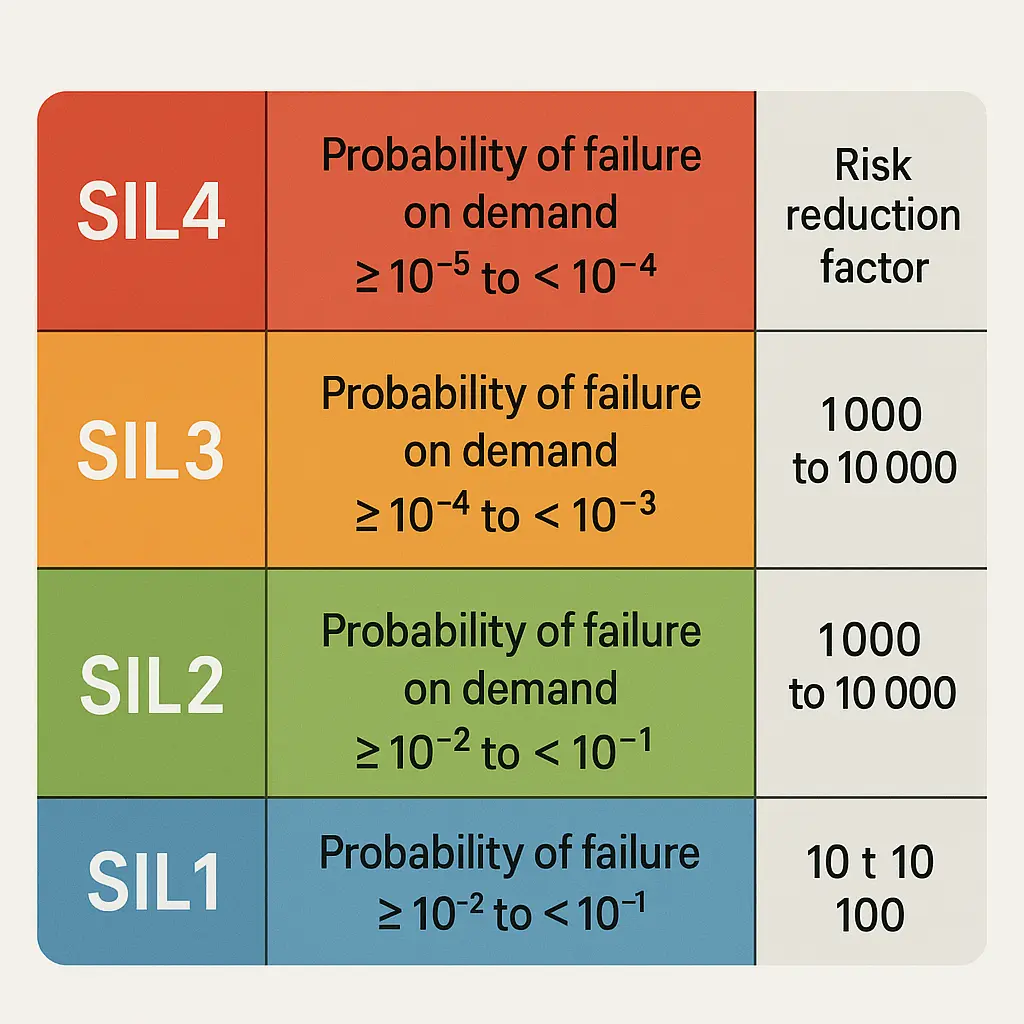

SIL Classification Levels

The SIL system is divided into four levels, designated as SIL 1 to SIL 4, with each level representing different degrees of risk reduction:

SIL Level |

Probability of Failure on Demand (PFD) |

Risk Reduction Factor (RRF) |

Application in Oil & Gas |

|---|---|---|---|

| SIL 1 | 0.1 to 0.01 (10⁻¹ to 10⁻²) | 10 to 100 | Basic safety requirements, low-risk scenarios |

| SIL 2 | 0.01 to 0.001 (10⁻² to 10⁻³) | 100 to 1,000 | Medium safety level, moderate-risk processes |

| SIL 3 | 0.001 to 0.0001 (10⁻³ to 10⁻⁴) | 1,000 to 10,000 | High safety level, critical safety functions |

| SIL 4 | 0.0001 to 0.00001 (10⁻⁴ to 10⁻⁵) | 10,000 to 100,000 | Highest safety level, rarely used in oil & gas |

For the process industry sector, including oil and gas, SIL levels typically range from SIL 1 to SIL 3, with SIL 4 being rarely implemented due to practical limitations.

Standards and Regulations

SIL implementation in oil and gas is governed by several international standards:

Primary Standards:

-

IEC 61508: The umbrella standard for functional safety of electrical/electronic/programmable electronic safety-related systems

-

IEC 61511: Process sector-specific implementation of IEC 61508, specifically for Safety Instrumented Systems

-

ANSI/ISA 84: American standard that mirrors IEC 61511 content

Supporting Standards:

-

OISD-150 and OISD-179: Indian standards for oil and gas safety

-

OSHA 29 CFR Part 1910.119: Process Safety Management requirements

SIL Assessment Methodology

The SIL assessment process involves several key steps:

1. Hazard Identification and Risk Analysis

-

Conduct Process Hazard Analysis (PHA) or HAZOP studies

-

Identify potential hazardous events and their consequences

-

Define initiating events such as high pressure, low flow, or equipment failure

2. Safety Instrumented Function (SIF) Identification

-

Identify SIFs from P&IDs and Cause & Effect matrices

-

Determine functions critical to process safety

3. Layer of Protection Analysis (LOPA)

-

Identify Independent Protection Layers (IPLs) such as:

-

Pressure Safety Valves (PSVs)

-

Emergency Shutdown (ESD) systems

-

Control systems

-

Operator intervention

-

4. Risk Reduction Factor Calculation

-

Calculate the required risk reduction using the formula:

-

RRF = Unmitigated Event Frequency / Tolerable Event Frequency

-

-

Assign appropriate SIL level based on calculated RRF

5. SIL Verification

-

Verify that the designed safety system can achieve the target SIL

-

Use methods such as Fault Tree Analysis (FTA) or Reliability Block Diagrams

Practical Examples in Oil and Gas Refinery Applications

SIL assessments have been successfully implemented across major refineries:

IOCL Mathura Refinery – Covered 19 process units including:

-

Atmospheric Vacuum Unit (AVU)

-

Fluidized Catalytic Cracking Unit (FCCU)

-

Continuous Catalytic Reforming Unit (CCRU)

-

Hydrogen Generation Units (HGU-I & II)

IOCL Panipat Refinery – Assessed 30+ units including:

-

Resid Fluidized Catalytic Cracking Unit (RFCCU)

-

Sulphur Recovery Unit (SRU)

-

High-Density Polyethylene Unit (HDPE)

Typical SIL Applications

SIL 1 Applications:

-

Basic flow control systems

-

Non-critical temperature monitoring

-

Low-consequence pressure relief

SIL 2 Applications:

-

Moderate-risk chemical processing

-

Fire and gas detection systems

-

Emergency ventilation systems

SIL 3 Applications:

-

Emergency shutdown systems for critical equipment

-

High-pressure gas processing

-

Toxic gas detection and mitigation systems

Benefits of SIL Implementation Safety Enhancement

-

Accident Prevention: Proper SIL classification significantly reduces the risk of catastrophic failures, explosions, fires, and toxic releases

-

Personnel Protection: Ensures safety systems are robust enough to protect worker lives

-

Environmental Protection: Minimizes environmental impact from process failures

Operational Benefits

-

Increased Uptime: SIL 3-certified equipment delivers consistent performance with minimal failures, reducing costly downtime

-

Cost Efficiency: Preventive approach reduces potential financial losses from accidents and business interruption

-

Regulatory Compliance: Meets international safety standards and regulatory requirements

Business Advantages

-

Risk Management: Provides quantitative basis for risk-based decision making

-

Insurance Benefits: May result in reduced insurance premiums due to improved safety profile

-

Reputation Protection: Demonstrates commitment to safety and responsible operations

Components of Safety Instrumented Systems

A typical SIS in oil and gas applications consists of three main elements:

Input Elements (Sensors):

-

Pressure transmitters

-

Temperature sensors

-

Flow meters

-

Level indicators

-

Gas detectors

Logic Solver:

-

Programmable Logic Controllers (PLCs)

-

Safety PLCs certified to IEC 61508

-

Dedicated safety controllers

Final Elements:

-

Safety valves (SIL 3-certified)

-

Emergency shutdown valves

-

Actuators and solenoids

-

Fire suppression systems

Challenges and Considerations Technical Challenges

-

Proof Testing: Regular testing required to maintain SIL integrity, typically at 1-3 year intervals

-

Common Cause Failures: Must consider potential for multiple component failures from single cause

-

Systematic Failures: Software and human factors can impact overall system reliability

Implementation Considerations

-

Cost vs. Risk: Higher SIL levels require more expensive, redundant systems

-

Maintenance Requirements: Increased complexity requires specialized maintenance procedures

-

Training Needs: Personnel must be trained on SIL concepts and system operation